BEST BASKET MILL

-

Payment

L/C(sight) , T/T

-

MOQ

1 Set

-

Supply Ability

9,999,999 Set per One-Time

-

Supply Details

Customization Limited goods

Negotiable

-

Country of sale

Asia, Middle East, Americas, Europe, World Wide

-

PRICE

-

FOB

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model BTFM-10, BTFM-30BEST CHEMICAL MACHINE Co., Ltd.

-

origin

Republic of Korea

-

Size(Capacity)

60HP, 50HP, 30HP, 10HP, 2HP (MAIN MOTOR)

-

Function

It finely disperses and grinds chemical particles(ex. pigment) through high-speed collision and shea

-

Material

Composite(Steel, Stainless ...)

-

Color

Light Blue (Can be ustomized)

-

Style

Option(Explosion-proof)

-

Condition

New(Option: Overhauled)

-

Features

Vertical-type Mill

PRODUCT DESCRIPTION

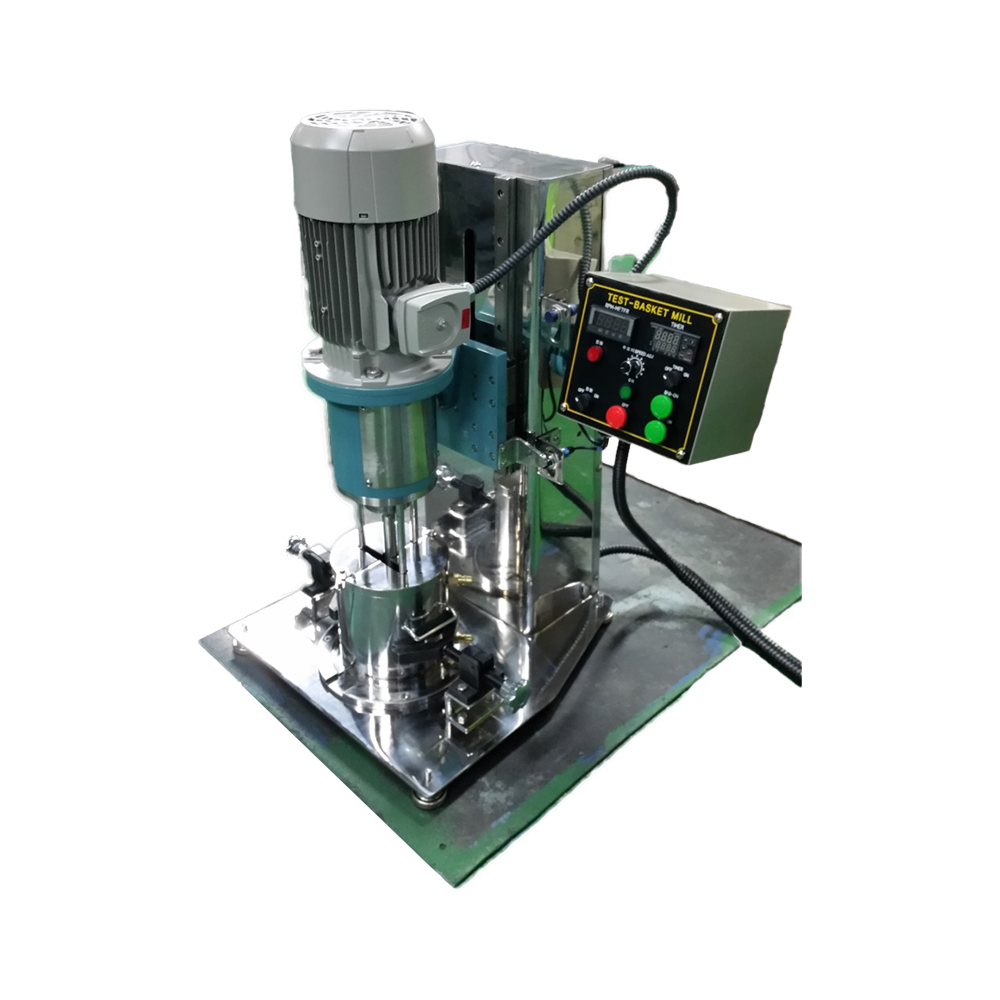

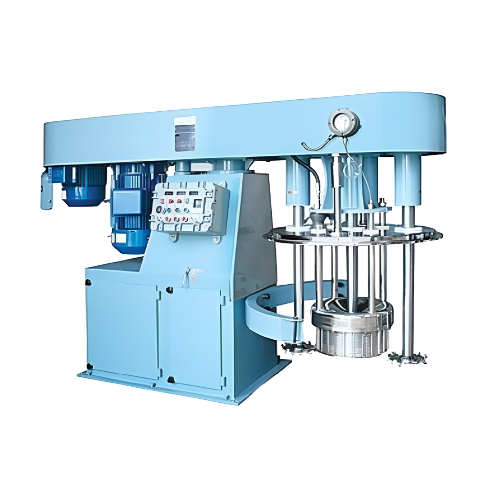

BEST BASKET MILL

Basket Mill Introduction

The Basket Mill is an innovative dispersion device that can perform mixing and dispersion processes simultaneously within a single unit. Inside a container filled with raw materials, the basket—containing beads and a high-speed impeller—generates intense shear and collision forces, enabling uniform and stable dispersion in a short time.

The Basket Mill is particularly advantageous for small-lot and multi-product production, as well as processes requiring quick changeovers and easy cleaning. The basket (vessel) can be conveniently replaced, allowing flexible adaptation to various batch conditions. With its simple structure and user-friendly operation, it enhances overall work efficiency.

In addition, the powerful shear and friction forces created by high-speed rotation provide excellent energy efficiency, delivering narrow particle size distribution and highly reproducible results. Thanks to these features, the Basket Mill is widely used not only in laboratories, pilot plants, and customized specialty production, but also across industries such as inks, paints, pigments, coatings, and electronic materials.

The Basket Mill is more than just a piece of equipment—it is a next-generation dispersion solution that simultaneously improves process efficiency and product quality.

Key Features

- Integrated Mixing & Dispersion: Mixing and dispersion are performed simultaneously in a single unit, reducing process time and improving productivity.

- Ideal for Small-Lot Production: Quick basket changeover and easy cleaning make it suitable for laboratories, pilot-scale production, and customized multi-product, small-lot manufacturing—perfectly optimized for batch processes.

- Ease of Operation: Its simple structure and intuitive controls allow even first-time operators to use it with ease, while cleaning and maintenance are straightforward.

- High Energy Efficiency: The high-speed impeller and beads inside the basket generate strong shear and friction forces, achieving high dispersion efficiency in a short time.

- Stable Quality: Short processing time and uniform energy transfer result in narrow particle size distribution and highly reproducible dispersion quality.

- Ideal for Small-Lot Production: Quick basket changeover and easy cleaning make it suitable for laboratories, pilot-scale production, and customized multi-product, small-lot manufacturing—perfectly optimized for batch processes.

- Ease of Operation: Its simple structure and intuitive controls allow even first-time operators to use it with ease, while cleaning and maintenance are straightforward.

- High Energy Efficiency: The high-speed impeller and beads inside the basket generate strong shear and friction forces, achieving high dispersion efficiency in a short time.

- Stable Quality: Short processing time and uniform energy transfer result in narrow particle size distribution and highly reproducible dispersion quality.

Company Overview

BEST CHEMICAL MACHINE Co., Ltd. specializes in designing and manufacturing high-performance mixing and dispersion equipment for industries such as inks, paints, adhesives, coatings, and chemical solutions.

Our advanced horizontal bead mills, basket mills, and mixers deliver precise, uniform, and stable processing, ensuring high product quality and reproducibility. With a focus on energy efficiency, durability, and user-friendly operation, our equipment supports both small-scale laboratory batches and large-scale production.

Committed to innovation and customer success, BEST provides reliable solutions that enhance productivity and product performance.

Our advanced horizontal bead mills, basket mills, and mixers deliver precise, uniform, and stable processing, ensuring high product quality and reproducibility. With a focus on energy efficiency, durability, and user-friendly operation, our equipment supports both small-scale laboratory batches and large-scale production.

Committed to innovation and customer success, BEST provides reliable solutions that enhance productivity and product performance.

Other Products

R&D CERTIFICATE

-

- Attestation of Conformity

- kiwa

- 2025.01.13

- 인증서보기

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Telegraphic Transfer : T/T

- Name : JINHO KIM

SHIPPING

Shipping from :

Republic of Korea

- 76 Seokcheon-ro 494beon-gil Ojeong-gu, Bucheon-si, Gyeonggi-do (14446)

BEST CHEMICAL MACHINE Co., Ltd.

The person in charge

JINHO KIMAddress

76 Seokcheon-ro 494beon-gil Ojeong-gu, Bucheon-si, Gyeonggi-do (14446)

Introduction

BEST CHEMICAL MACHINE Co., Ltd. specializes in designing and manufacturing high-performance mixing and dispersion equipment for industries such as inks, paints, adhesives, coatings, and chemical solutions.

Our advanced horizontal bead mills, basket mills, and mixers deliver precise, uniform, and stable processing, ensuring high product quality and reproducibility. With a focus on energy efficiency, durability, and user-friendly operation, our equipment supports both small-scale laboratory batches and large-scale production.

Committed to innovation and customer success, BEST provides reliable solutions that enhance productivity and product performance.

-

- Business Type :

- Manufacturer

-

- Main Product :

- pin mill, agitator, basket mill

-

- Established :

- 1989-02-01

-

- Total Annual Revenue :

-

- Total Employees :

- Less than 5

R&D CERTIFICATE

-

- Attestation of Conformity

- kiwa

- 2025.01.13

- 인증서보기

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- Less than 5

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

- MEMBER

- BEST CHEMICAL MACHINE Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★

![[BEST CHEMICAL MACHINE] BEST DISPERSER (MIXER)](/image/goodsImage.do?goods_no=GS2025102349654&image_se_code=MAIN_THUMB174)