ITEM SPECIFICS

-

Brand

SK-on

-

origin

Republic of Korea

-

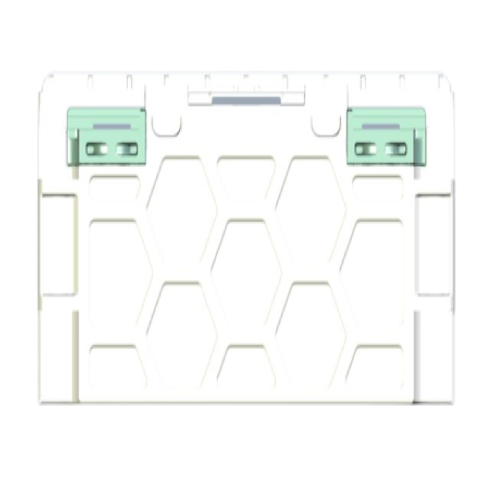

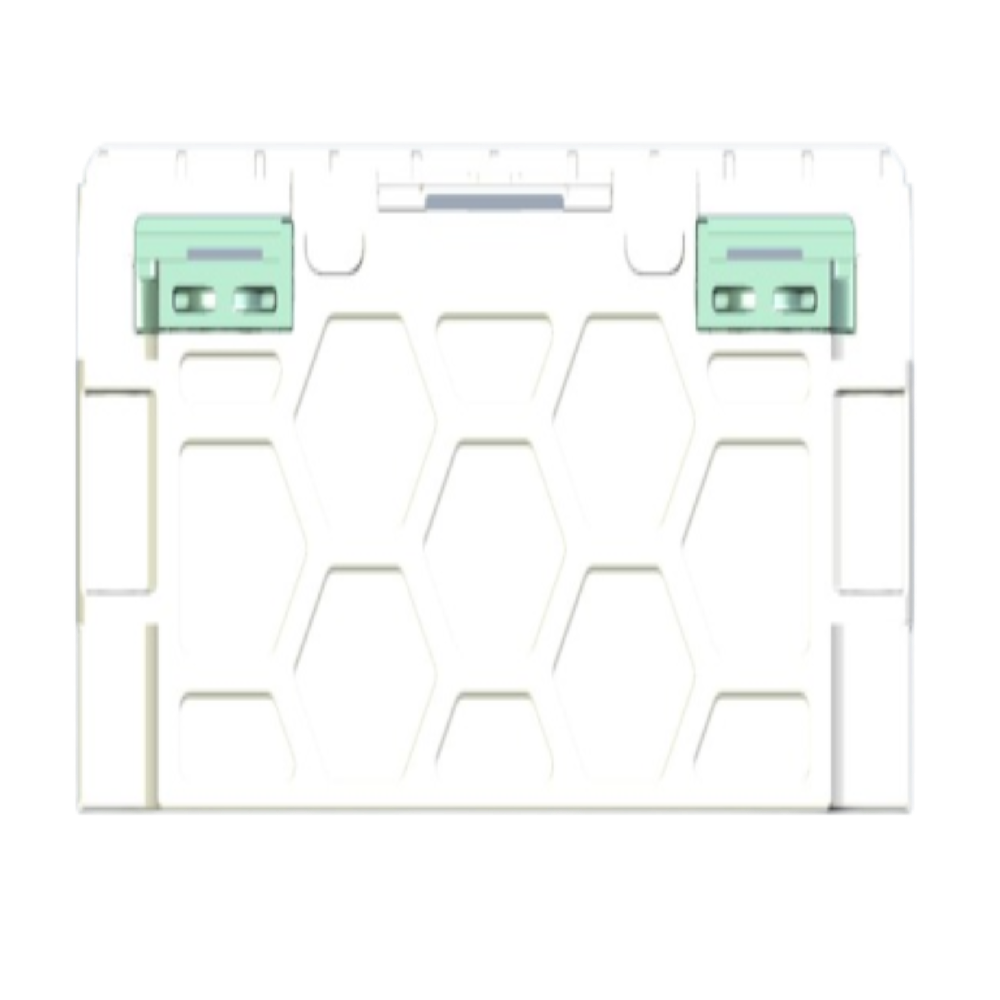

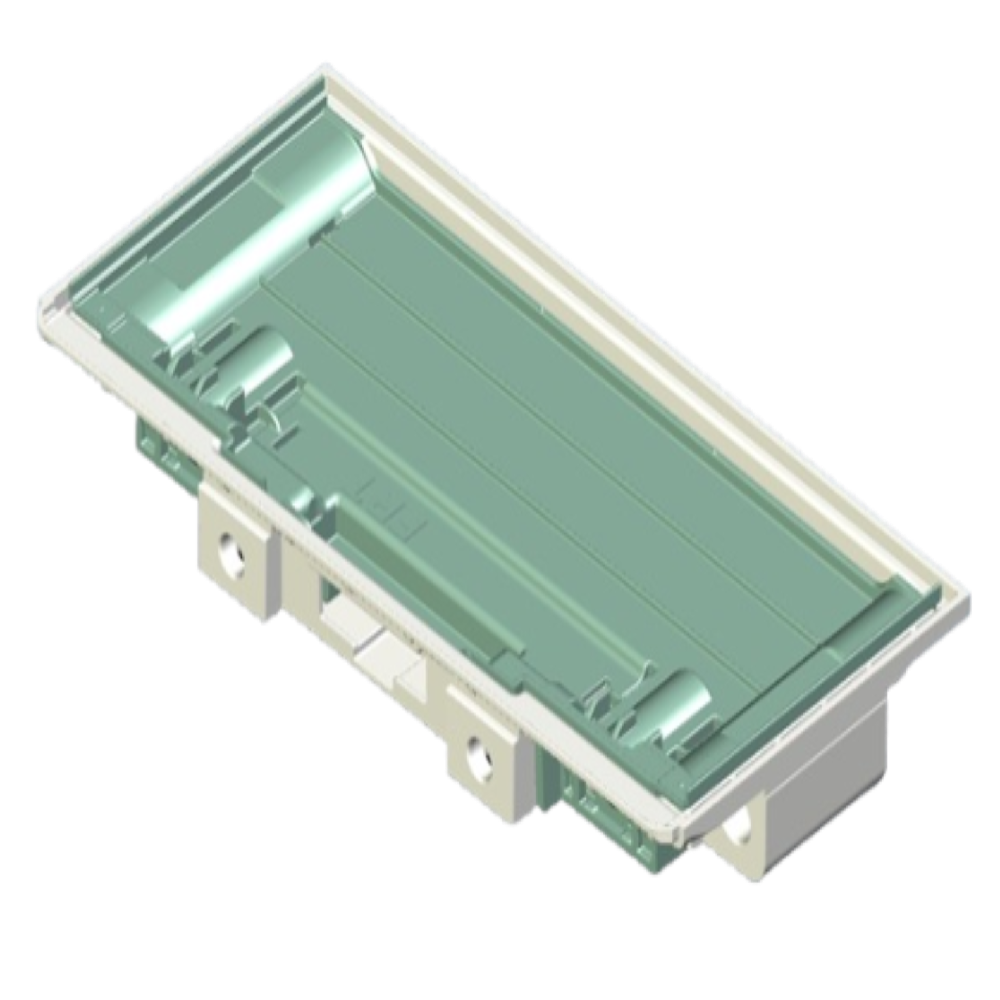

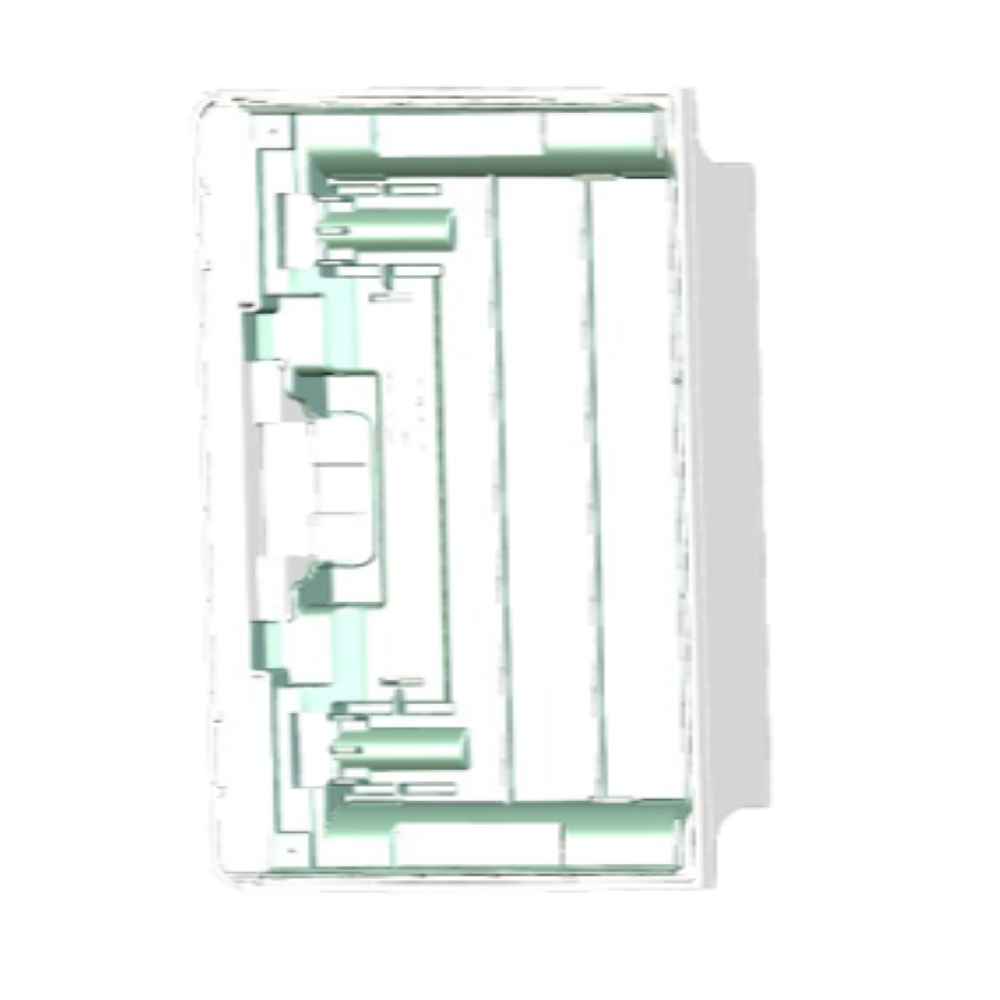

Size(Capacity)

225*106*27.5

-

Color

Gray

-

Material

ALDC12

-

Weight

323g

PRODUCT DESCRIPTION

The product described above is manufactured using the aluminum alloy ALDC12, a widely adopted material in the automotive parts industry due to its excellent castability, high corrosion resistance, and reliable mechanical strength. In the production process, the alloy is first melted at a controlled temperature to ensure uniformity and then injected into a precision-engineered mold. After solidification, the component undergoes several finishing steps such as trimming, deburring, and shot blasting, which remove excess material, smooth sharp edges, and improve the surface quality. Subsequent machining operations are carried out to achieve the exact dimensional tolerances and functional specifications required by the automotive sector. The final product is applied as a protective cover for vehicle batteries. Its primary role is to shield the battery from external impacts, environmental factors such as dust, moisture, and heat, and potential mechanical damage that may occur during vehicle operation. By ensuring a stable housing for the battery, this component contributes not only to vehicle safety but also to the overall durability and efficiency of the electrical system.

R&D CERTIFICATE

-

- CERTIFICATE OF SUPPLIER QUALITY

- 인증서보기

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : EUNSUN CHOI

SHIPPING

Shipping from :

Republic of Korea

- 91 Gongdan 8-ro Jillyang-eup, Gyeongsan-si, Gyeongsangbuk-do (38465)

KUNHWA ENG CO., LTD.

KUNHWA ENG CO., LTD.

Seller_MailThe person in charge

YONGHOON HURAddress

91 Gongdan 8-ro Jillyang-eup, Gyeongsan-si, Gyeongsangbuk-do (38465)

Introduction

Based on its accumulated technology and experience, Kunhwa EnG has been manufacturing Rubber products and Aluminum Diecasting since 1965 by the name of "Kunhwa" with specialized and advanced technology. We are doing our best for new material development and analyzing customer's need. In keeping with globalization of automotive industry, Kunhwa EnG has established oversea addiliates in China, India, and Mexico to strengthen its global competitiveness and dream of leaping into the global market through securing future technolgies. We are doing our utmost to improve quality by prompt responds to changes in demand with the attitude of creation and challenge. We promise that Kunhwa EnG, the leading company in the automotive field, will be a reliable partner who will be the foundation for the growth and development of the automotive industry and will always be with you.

-

- Business Type :

- Manufacturer

-

- Main Product :

- ENGINE MOUNTING

-

- Established :

- 2005-12-16

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 101~500 people

R&D CERTIFICATE

-

- CERTIFICATE OF SUPPLIER QUALITY

- 인증서보기

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- 101~500 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

- MEMBER

- KUNHWA ENG CO., LTD.

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★

SUPPLIER BEST

- No Items