Hana Weltech Ceramix Solution

-

Payment

L/C(sight)

-

MOQ

1 square metres(m2)

-

Supply Ability

0 square metres(m2) per One-Time

-

Supply Details

Customization

Custom production available

-

Country of sale

Asia, Americas, Middle East, Africa, World Wide

-

PRICE

-

FOB

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model HW-CER-PIPEHana Weltech

-

origin

Republic of Korea

-

Size(Capacity)

Inner diameter 100A or more PIPE

-

Function

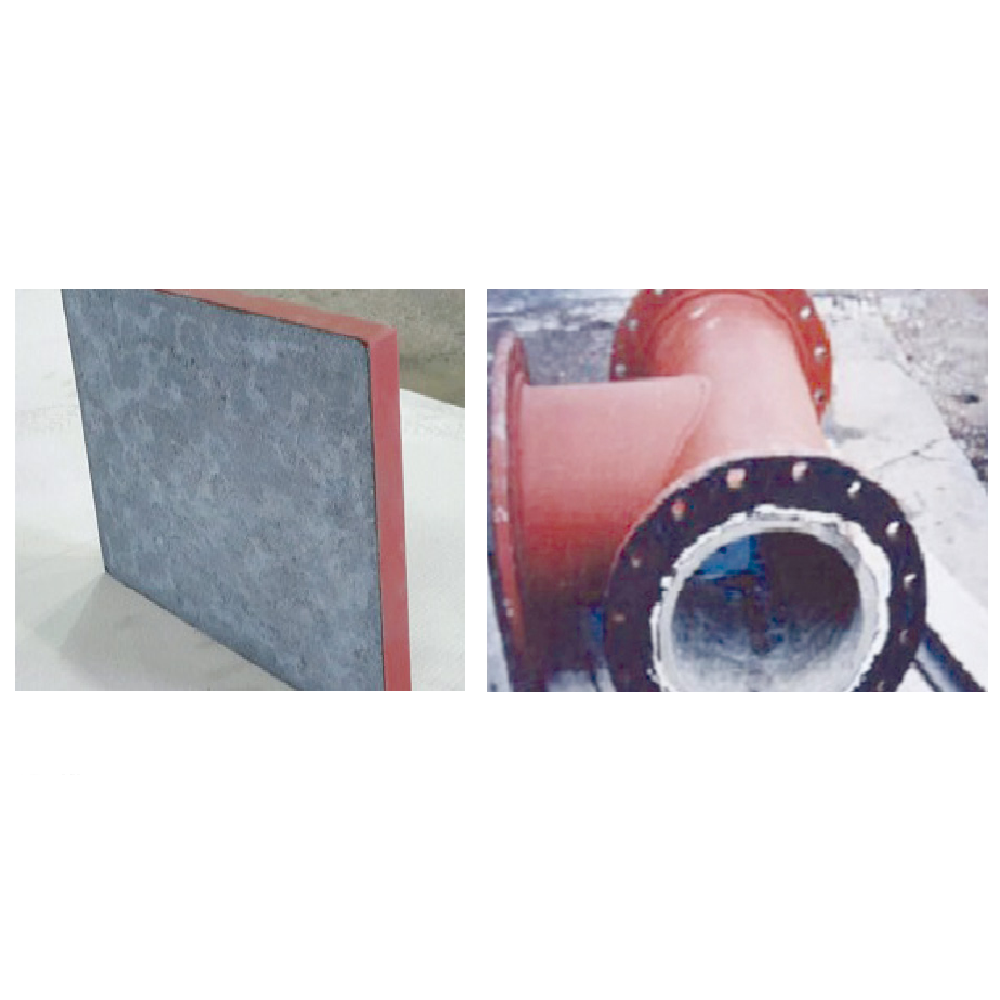

Wear-resistant ceramic lining applied pipe

-

Material

Existing pipe material and mixed ceramic material

-

Features

Implementation of various shapes such as straight pipe and curved pipe

-

Color

decide after consultation

-

Expiry Date

semi-permanent

-

Condition

New

-

Gender

Male and female

-

age-appropriate

Adults

PRODUCT DESCRIPTION

HANA Weltech Ceramix Solution

Product Description

1. Ceramix process is comprised of Ceramix-1, Ceramix-Cast and Ceramix-Liner. Ceramix-1 is a trowelling technology using special ceramic mortar manually to form an excellent wear resistant lining which is capable of in-situ service. Ceramix-Cast is a cast process which forms monolithic ceramic compounds such as inner liner of coal transport elbow and burner parts for wear and high temperature application.

And Ceramix- Liner is the newest anti-abrasive ceramic liner which change the conventional lining market such as hard-facing, hardox and ceramic tiling. The features of Ceramix is different from other general refractories. Consisting of 15-70w% of Sic empowers outstanding wear and high temperature resistance of lining.

And Ceramix- Liner is the newest anti-abrasive ceramic liner which change the conventional lining market such as hard-facing, hardox and ceramic tiling. The features of Ceramix is different from other general refractories. Consisting of 15-70w% of Sic empowers outstanding wear and high temperature resistance of lining.

2. Ceramix-Liner is newest anti-abrasion ceramic liner which can be fastened with bolt. The abrasive performance of Ceramix is generally equivalent to Al2O3 ceramic tile(10 times of hardox or 5 times of

hard-faced) but it doesn’t crack or peel off asaposed to ceramic tile. Moreover, the thickness of Ceramix Liner is 4 to 5 times thicker than general ceramic tile(ceramic tile: 7~15mm, ceramix: 30~35mm), so the

service life time of Ceramix-Liner is uncomparable with any types of liner.

3. Regarding the service environments the materials can be adjusted with variety of oxides and carbides. Comparing to the conventional ceramic tiling process, Ceramix-Cast is much more fast and easy and

the performance is far superior. Ceramix-Cast is composed of monolithic wear resistant ceramic lining and inner-lining of small-diameter pipe is available.

Company Overview

HANAWELTECH creates new values of energy, industrial and infrastructure markets pursuing the biggest value of thinking creative.

Our specialized and well experienced engineering teams are determined problem solvers of high-temperature, abrasion, erosion and corrosion.

Our specialized and well experienced engineering teams are determined problem solvers of high-temperature, abrasion, erosion and corrosion.

We provide efficient solutions improving our customer’s performance and life-cycle costs with practical applications.

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Name : Jeongmok Lee

SHIPPING

Shipping from :

Republic of Korea

- 32 63-ro (07345)

- Sea Freight : Please contact us for carriers inquiry

- Sea Freight : impossible

- Please contact your administrator for detailed information.

- Name : Jeongmok,Lee

- Tel : 82-02-786-0985

HANAWELTECH Co., Ltd.

The person in charge

Jaewoo JungAddress

32 63-ro, Yeongdeungpo-gu, Seoul (07345)

QR CODE

HANAWELTECH Co., Ltd.

Introduction

Welcome !

Welcome to our e-catalog home.

Here you can find information about our products. You can also send us inquiries and post comments about our company and products.

We hope you enjoy your visit.

HANAWELTECH creates new values of energy, industrial and infrastructure markets pursuing the biggest value of thinking creative.

Our specialized and well experienced engineering teams are determined problem solvers of high-temperature, abrasion, erosion and corrosion. We provide efficient solutions improving our customer’s performance and lifecycle costs with practical applications.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Burner Nozzle Tip, Flame Holder

-

- Established :

- 2010-01-04

-

- Total Annual Revenue :

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

-

- ISO 14001

- KMR

- 12/14/2024

- 인증서보기

-

- ISO 45001

- KMR

- 12/14/2024

- 인증서보기

-

- Power Plant Maintenance Qualified Company

- Korea South-East Power CO. and 4 Other Power Compa

- 10/16/2020

- 인증서보기

-

- Certificate of Innovative Product

- Ministry of SMEs and Startups

- 12/26/2022

- 인증서보기

-

- Power Plant Maintenance Qualified Company

- Korea South-East Power CO. and 4 Other Power Compa

- 01/29/2024

- 인증서보기

-

- ISO 9001

- KMR

- 12/14/2024

- 인증서보기

-

- ISO 14001

- KMR

- 12/21/2024

- 인증서보기

-

- ISO 45001

- KMR

- 12/21/2024

- 인증서보기

-

- Certificate of Approval

- Korea South-East Power CO. and 4 Other Power Compa

- 01/29/2024

- 인증서보기

-

- ISO 9001

- KMR

- 2024.12.14

- 인증서보기

-

- ISO 14001

- KMR

- 2024.12.21

- 인증서보기

-

- ISO 45001

- KMR

- 2024.12.21

- 인증서보기

-

- Certificate of Approval

- Korea South-East Power CO. and 4 Other Power Compa

- 2024.01.29

- 인증서보기

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

- MEMBER

- HANAWELTECH Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★